Mexico Overtakes China in USA Imports – Paving the Way for Energy Fabrication Evolution

General Market Shift Toward Mexico

In a significant shift, Mexico emerged as the foremost source of imports for the US, outstripping China for the first time in over two decades. The value of imports from Mexico to the US surged by nearly 5% in 2023, surpassing $475 billion, while China experienced a stark decline of 20% to $427 billion during the same period. This divergence in import values underscores a notable reconfiguration in trade dynamics, spurred by escalating tensions between the US and China, including the imposition of tariffs. The intensifying trade friction between the two economic powerhouses likely propelled US companies to reevaluate and diversify their supply chains, seeking alternatives to mitigate risks and ensure continuity of operations. With a focus on proximity and efficiency, many companies have strategically shifted production closer to home, with Mexico emerging as a prime beneficiary. Mexico’s geographical proximity to the US and its existing trade agreements offer a compelling advantage, facilitating seamless trade and logistics while reducing reliance on distant suppliers. One key driver behind this shift is Mexico’s competitive manufacturing costs, which often prove to be more favorable compared to other overseas options. By tapping into Mexico’s cost-effective labor pool and production capabilities, US companies can enhance their competitiveness and streamline operations, ultimately bolstering their bottom line. Moreover, the reduced dependence on China for imports not only enhances the resilience of the US supply chain but also aligns with broader geopolitical and economic considerations. As tensions persist and uncertainties loom over US-China relations, diversifying supply chains and fostering regional trade partnerships become imperative strategies for ensuring stability and mitigating risks.This emerging trend reflects a larger paradigm shift in global trade patterns, characterized by a resurgence of regionalization. As companies increasingly prioritize proximity, agility, and resilience in their supply chain strategies, regional trade blocs and partnerships are poised to play an increasingly pivotal role in shaping the future of international commerce. In this context, Mexico’s ascent as a leading supplier to the US signals not only a strategic repositioning of supply chains but also underscores the evolving dynamics of global trade in the 21st century.

Manufacturing and Fabrication for the Oil Industry

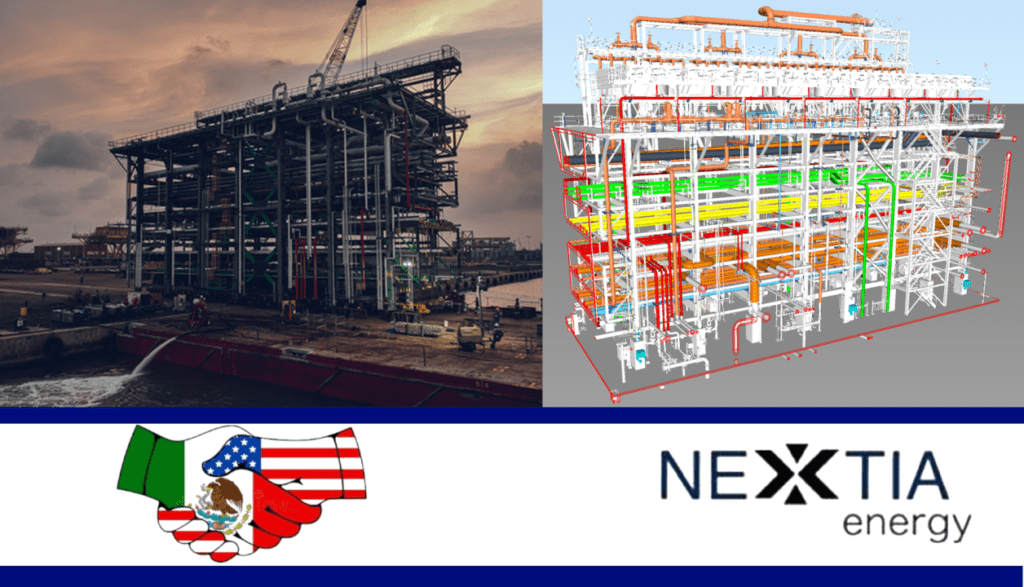

Continuing the trend of shifting supply chains and trade dynamics, Nextia Energy anticipates that this pattern will persist, particularly concerning fabrication requirements in the energy sector. As companies increasingly prioritize proximity, efficiency, and resilience in their supply chain strategies, the energy industry is expected to follow suit. Given the critical nature of energy infrastructure and the growing emphasis on domestic production and security, there is a heightened focus on optimizing fabrication processes and reducing reliance on distant suppliers. Mexico, with its strategic advantages in proximity to the US market, established trade agreements, and competitive manufacturing costs, is well-positioned to meet the fabrication needs of the energy sector. Nextia Energy foresees continued momentum in sourcing fabrication services from Mexico, leveraging the country’s expertise and infrastructure to support the development of energy projects. Moreover, as the global energy landscape undergoes rapid transformation, with increasing demand for renewable energy solutions and decarbonization efforts, the fabrication requirements in the energy sector are expected to evolve accordingly. Nextia Energy anticipates that Mexico will play a pivotal role in meeting these evolving fabrication needs, capitalizing on its skilled workforce, technological capabilities, and commitment to sustainability. By aligning with this anticipated trend and strategically partnering with Mexico-based fabricators, Nextia Energy aims to enhance project efficiency, reduce costs, and mitigate risks associated with global supply chain disruptions. Through proactive planning and collaboration, Nextia Energy endeavors to remain at the forefront of the evolving energy landscape, driving innovation and sustainability in the fabrication sector through key partnership to offer turnkey fabrication solutions.

Fabrication in Mexico Advantages

Performing modules fabrication for LNG, oil and gas and upstream processing equipment in Mexico with Nextia Energy and key partners presents numerous advantages:

- Strategic Access to North American Markets: Nextia Energy’s fabrication yard located in Mexico’s and in proximity to the United States and Canada provides strategic access to North American markets. With the United States being one of the largest consumers of LNG oil and gas products, manufacturing in Mexico with Nextia Energy allows for quicker responsiveness to market demands. This proximity also facilitates easier coordination with project stakeholders and reduces communication barriers, ultimately enhancing project efficiency.

- Integrated Supply Chains: Nextia Energy’s integration into North American supply chains offers additional benefits for companies involved in LNG and oil and gas projects. With established links to suppliers and service providers in Mexico, United States and Canada, Nextia Energy benefit from streamlined procurement processes and logistics, reduced lead times, reduced supply chain disruptions, and enhanced coordination throughout the supply chain and overall project resilience.

- Transportation Savings: Mexico’s geographical proximity significantly reduces transportation costs compared to shipping from Asia or the Middle East. The shorter shipping distances translate to lower freight costs, decreased fuel consumption, and reduced transit times, ultimately leading to substantial savings in logistics expenses for companies involved in LNG, oil, and gas projects.

- Reduced Risk during Transportation: Transporting large and heavy modules over long distances, especially across oceans, poses inherent risks such as damage, delays, and accidents. By manufacturing modules in Mexico with Nextia energy, companies can minimize these risks by opting for shorter shipping routes and avoiding the need to traverse through multiple international waters and high-risk areas. This reduction in transportation risk enhances project reliability and ensures timely delivery of critical components.

- Less Exposure to Sea Conditions: Shipping modules from Asia or the Middle East often entails navigating through various sea conditions, including rough waters, storms, and potential piracy-prone areas. By choosing Nextia Energy with manufacturing hub in Mexico, companies can mitigate exposure to these maritime risks, as the transportation routes are typically shorter and less susceptible to adverse weather conditions and security threats. This reduces the likelihood of damage or loss during transit and enhances overall project resilience.

- Regulatory Compliance and Trade Agreements: Nextia Energy proposed fabrication yards combined with Mexico’s adherence to stringent regulatory standards and its participation in trade agreements such as the United States-Mexico-Canada Agreement (USMCA) ensure compliance with quality, safety, and environmental regulations. By manufacturing modules in Mexico with Nextia energy, companies can align with these regulatory requirements seamlessly, minimizing regulatory risks and ensuring smooth project execution.

- Skilled Workforce and Established Industry: Nextia Energy and key partners boasts a skilled workforce with experience in the oil and gas industry, supported by a robust infrastructure of specialized yards and fabrication facilities. Nextia Energy’s and partner’s facilities have a proven track record of delivering high-quality modules and equipment, meeting the stringent demands of the global oil and gas sector. Leveraging our expertise and infrastructure ensures reliable fabrication processes and enhances project outcomes.

- Innovation and Technology Adoption: Mexico’s oil and gas industry is increasingly focused on innovation and technology adoption to improve efficiency, reduce costs, and minimize environmental impact. By manufacturing modules in Mexico with Nextia Energy, companies can access cutting-edge technologies, innovative processes, and best practices developed within the Mexican oil and gas sector, driving continuous improvement and innovation throughout the supply chain..

- Quality and Compliance Standards: our fabrication yards are known for adhering to international quality and compliance standards, ensuring that manufactured modules meet the rigorous requirements of the global oil and gas industry. By leveraging Nextia Energy Mexican yards’ commitment to quality and compliance, companies can mitigate risks associated with product defects, safety concerns, and regulatory non-compliance, ultimately enhancing project success and reputation.

Fabrication Expertise

Nextia Energy and its associated key partners possess extensive expertise and experience in the design, fabrication, and deployment of complex processing modules for various energy applications. This expertise spans across multiple facets of the energy sector, including oil and gas, LNG, renewable energy, and power generation. With state-of-the-art fabrication facilities and advanced manufacturing capabilities, Nextia Energy and its partners excel in the fabrication of intricate processing modules. Whether it’s modular components for oil and gas refineries, liquefaction plants for LNG facilities, or specialized equipment for renewable energy projects, they have the technical know-how and resources to deliver high-quality, custom-built solutions on time and within budget, including:

Electrical:

- Power Distribution Systems: High and low voltage electrical systems for distributing power throughout the module, including transformers, switchgears, and cabling.

- Control and Instrumentation Systems: Panels, wiring, and sensors for monitoring and controlling process parameters like temperature, pressure, and flow.

- Motor Control Centers: Equipment for managing electric motors driving pumps, compressors, and other machinery.

- Lighting Systems: Fixtures and wiring for general and task lighting within the module.

- Grounding and Earthing Systems: Measures to protect personnel and equipment from electrical hazards.

Mechanical:

- Pressure Vessels: Tanks and reactors designed to withstand high pressure and temperature for various processes.

- Heat Exchangers: Equipment for transferring heat between different process streams.

- Pumps and Compressors: Machinery for moving fluids and gasses throughout the module.

- Piping Systems: Extensive networks of pipes and valves for transporting fluids and gasses across the module.

- Rotating Equipment: Turbines, generators, and other rotating machinery for process operations.

- Structural Steelwork: Supporting framework for the entire module and its equipment.

Piping:

- Carbon Steel Piping: Used for general service applications like water, air, and low-pressure hydrocarbons.

- Alloy Steel Piping: Employed for high-temperature, high-pressure, and corrosive services.

- Stainless Steel Piping: Used for clean and sanitary applications or where corrosion resistance is crucial.

- Flanges, Valves, and Fittings: Various components for connecting, controlling, and directing flow within the piping systems.

- Insulation: Applied to piping to maintain process temperatures and prevent heat loss.

Conclusion

In summary, the collaboration between Nextia Energy and its associated key partners represents a combination of expertise, experience, and capabilities in delivering complex processing modules for diverse energy applications. By choosing to perform modules for LNG, oil and gas, and upstream processing equipment in Mexico with Nextia Energy, companies unlock a multitude of advantages that extend beyond mere cost-effectiveness and logistical efficiency. Fabricating modules with Nextia Energy in Mexico emerges as a strategic choice for companies looking to optimize their supply chains and enhance their competitiveness within the dynamic global oil and gas industry. Leveraging Nextia Energy’s expertise and experience, companies can navigate the complexities of the energy sector with confidence, capitalizing on the unique benefits offered by Mexico’s strategic location and established infrastructure. Partnering with Nextia Energy enables companies to tap into a wealth of resources and insights, tailored to the specific requirements of both the Mexican and US energy markets. With Nextia Energy’s deep understanding of local regulations, market dynamics, and industry best practices, companies can effectively navigate challenges and seize opportunities, ensuring the success of their ventures in Mexico’s dynamic oil and gas industry. In essence, in partnership with Nextia Energy, companies can optimize their supply chains, enhance project competitiveness, and capitalize on the abundant opportunities presented by Mexico’s thriving energy sector. Through collaborative efforts and strategic insights, Nextia Energy empowers companies to achieve their goals and drive sustainable growth in the ever-evolving landscape of the energy industry. For further inquiries and to explore how Nextia Energy can support your projects, please contact [email protected].

Published by